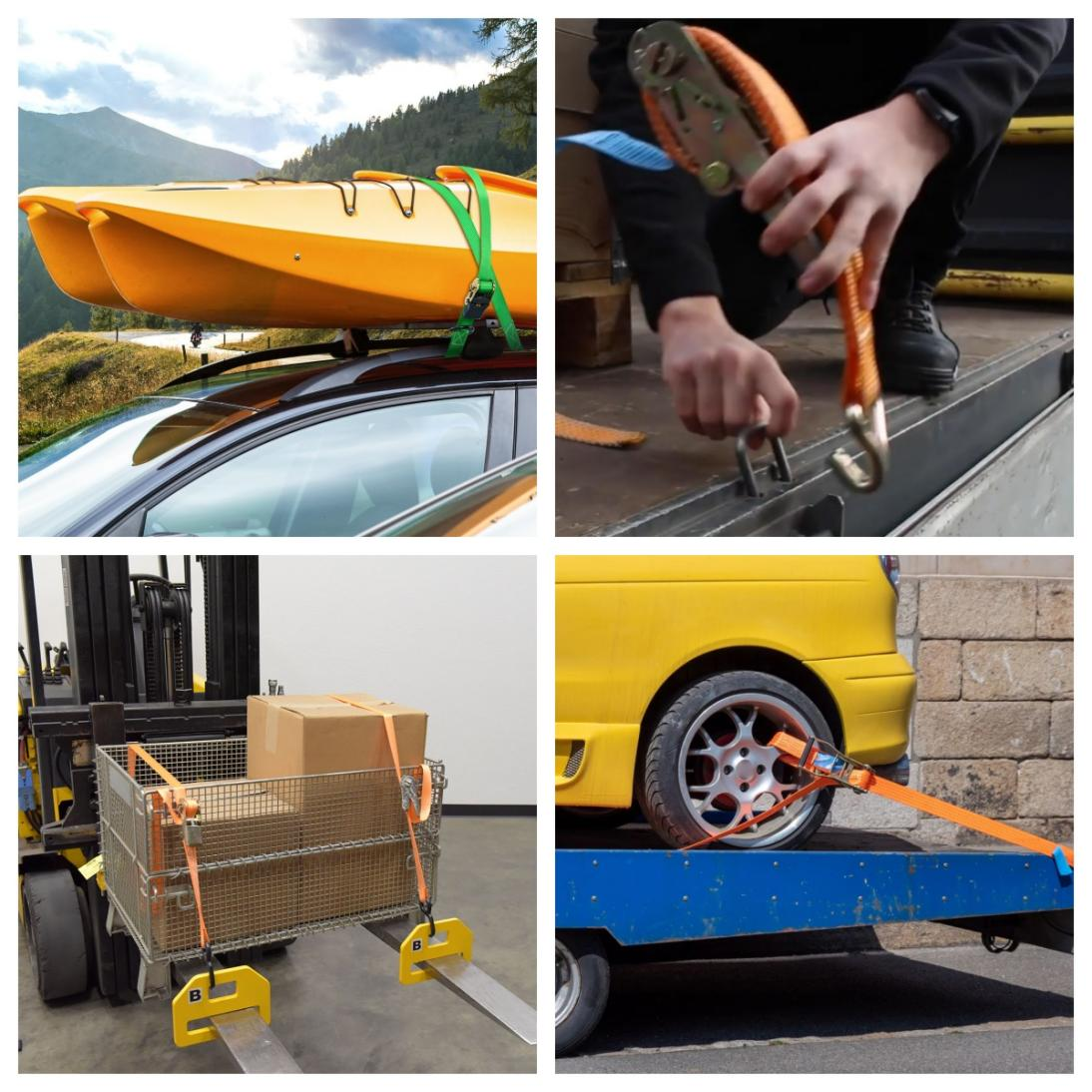

Ratchet straps are used to secure goods during transportation, movement, loading, or storage. They offer a secure, secure fit, are lightweight, easy to use, and protect objects from damage. They can be used in various environments, depending on the type of hook.

Advantages of Ratchet Strap:

- Time-saving and labor-saving. This product, with its powerful force, can be operated by one person, generating tremendous binding force and enabling quick tying and untying.

2. Safe and durable. This product is constructed of special steel components and strong, acid- and alkali-resistant fiber materials.

3. Easy to operate. Instantly tighten, never fall off. Instantly loosen, easy to operate, and easy to retract. It takes up very little space.

4. Safe for cargo. This product is constructed of flat fiber webbing, which distributes the stress points and is flexible, ensuring no damage to cargo. It is ideal for securing cargo during transportation, moving, loading, or storage. Once locked, it won’t fall off, ensuring safety and reliability. It is lightweight, easy to operate, and protects cargo from damage.

https://htsling.com/product-category/ratchet-tie-down-straps/

Product Information

- Material: 100% Polyester

- Safety Factor: 2:1, 3:1

- Standard: EN Standard, American Standard, Australian Standard

- Length: 6m, 8m, 10m, 12m (Customized Length Available)

- Width:European Standard(25MM-100MM),

American Standard(1”,2”,3”and 4”)

- Ratchet handle style: aluminum handle, iron handle, plastic handle, rubber coated

- Feature:

-Compatible with a wide range of accessories, including handles and hooks, for customizable load securing solutions

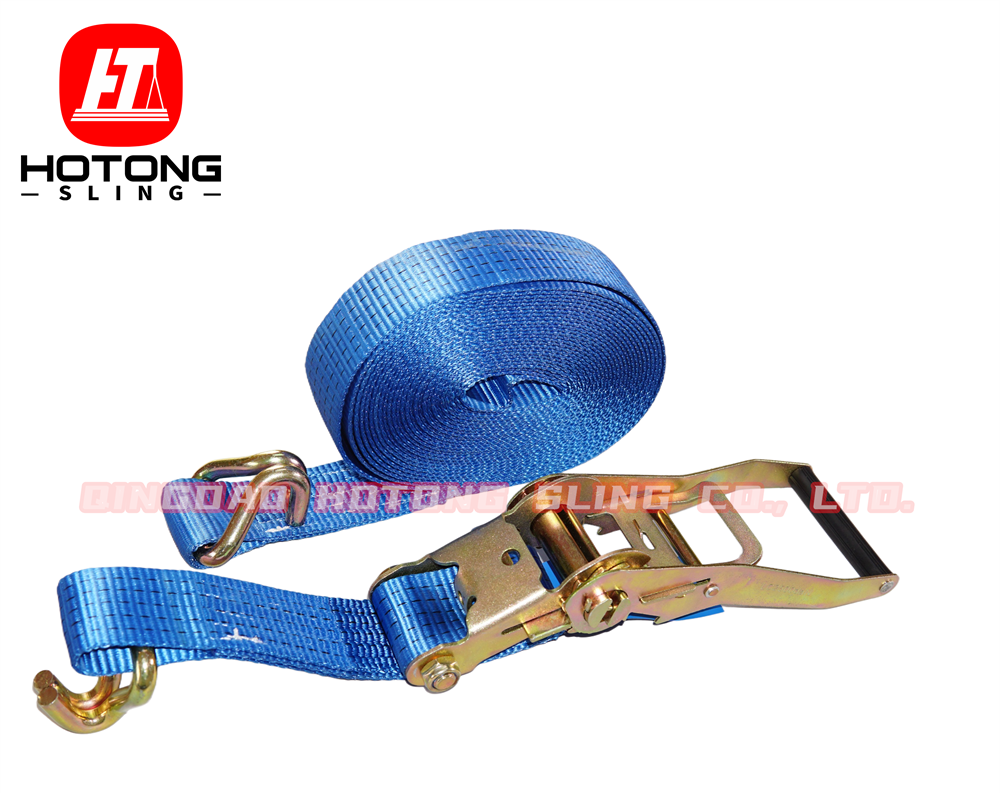

-The ratchet strap mainly consists of two parts: the long head and the short head.

-The short head has a ratchet and corresponding hook, while the long head is just a strap and hook.

-American Standard Mostly using Flat Hook and S hook,European Standard Mostly using Double J Hook

-Corrosion-resistant steel ratchet and hooks for increased durability

-Non-abrasive and gentle on cargo, preventing surface damage

- Application: Logistic cargo control

- Certification: CE, ISO9001, GS, TUV

- Marketing Channel: Importer, Wholesaler, Distributor.

Different Standards of Ratchet Straps

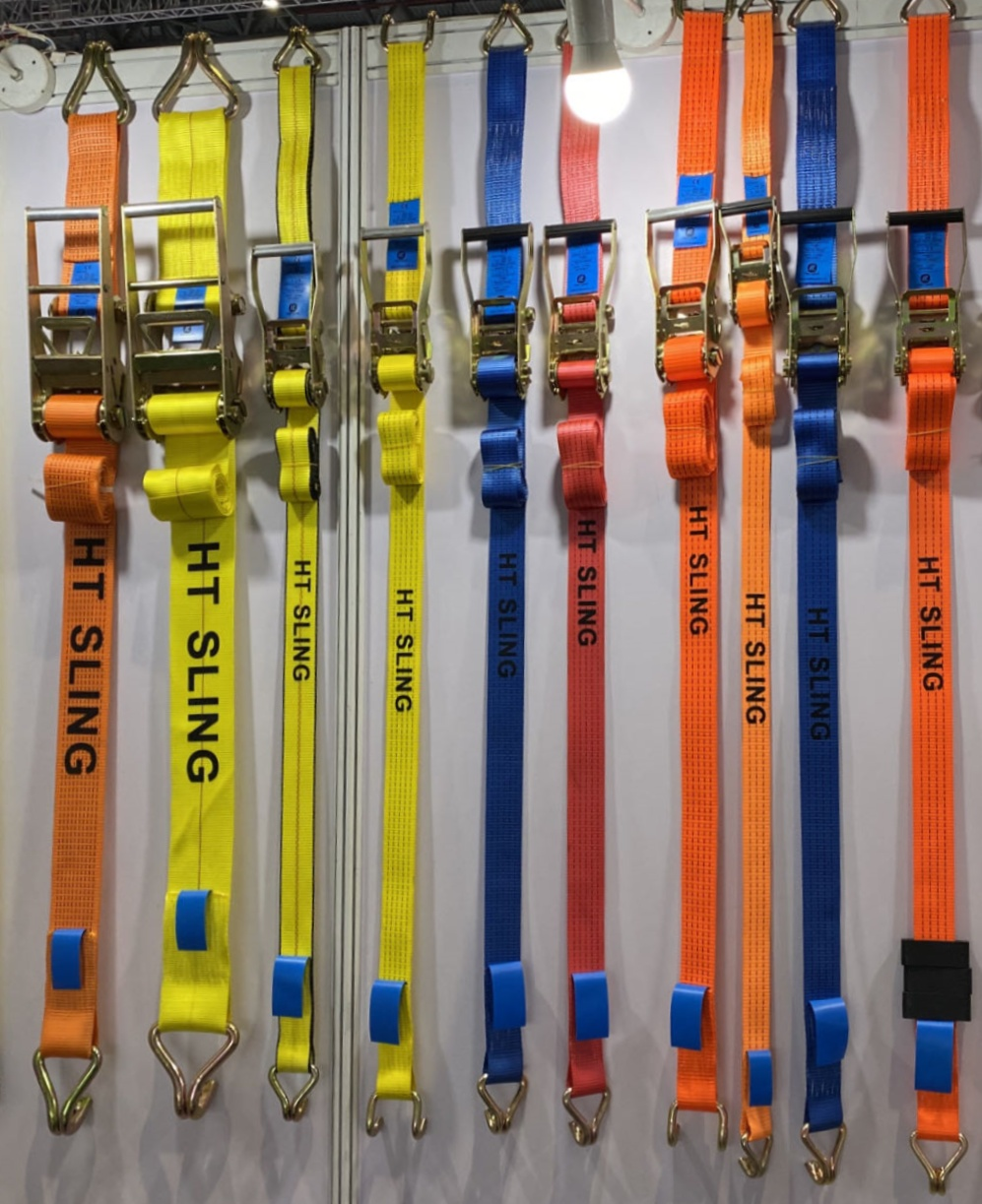

European Standard: Based on breaking force, straps are available in sizes such as 0.8T, 1T, 1.5T, 2T, 3T, 4T, 5T, 8T, and 10T. Available in any length. The number of lines on the strap generally represents the number of tons of tension. Colors include orange and blue.

| WIDTH | WORKING LOAD LIMIT | |

| (MM) | (LC) | (KG) |

| 25 | 400 | 800 |

| 25 | 500 | 1000 |

| 25 | 750 | 1500 |

| 35 | 1000 | 2000 |

| 35 | 1500 | 3000 |

| 50 | 1000 | 2000 |

| 50 | 1500 | 3000 |

| 50 | 2000 | 4000 |

| 50 | 2500 | 5000 |

| 75 | 4000 | 8000 |

| 75 | 5000 | 10000 |

| 100 | 5000 | 10000 |

American Standard: Based on breaking force, straps are available in sizes such as 1500lbs, 4500lbs, 10000lbs, and 16200lbs. Lengths are typically 20′, 27′, and 30′. Straps typically have one or two dotted lines. Yellow is the primary color.

| WIDTH | LENGTH | WORKING LOAD LIMIT | |

| (Inch) | (Feet) | (LBS) | (KGS) |

| 1 | 10 | 800 | 363 |

| 1 | 15 | 800 | 363 |

| 1 | 20 | 800 | 363 |

| 1 | 10 | 1000 | 454 |

| 1 | 15 | 1000 | 454 |

| 1 | 20 | 1000 | 454 |

| 2 | 15 | 3333 | 1497 |

| 2 | 27 | 3333 | 1497 |

| 2 | 30 | 3333 | 1497 |

| 2 | 40 | 3333 | 1497 |

| 2 | 12 | 1500 | 680 |

| 2 | 16 | 1500 | 680 |

| 2 | 20 | 1500 | 680 |

| 3 | 27 | 5400 | 2449 |

| 3 | 30 | 5400 | 2449 |

| 4 | 27 | 5400 | 2449 |

| 4 | 30 | 5400 | 2449 |

Australian Standard: Based on breaking force, straps are available in sizes such as 3T, 5T, and 10T. Available in any length. Straps are typically blue and often come with a wrapping cloth.

| WIDTH | LENGTH | WORKING LOAD LIMIT | |

| (MM) | (M) | (LC) | (KG) |

| 25 | 3 | 750 | 1500 |

| 25 | 4 | 750 | 1500 |

| 25 | 5 | 750 | 1500 |

| 25 | 6 | 750 | 1500 |

| 35 | 5 | 1500 | 3000 |

| 35 | 6 | 1500 | 3000 |

| 50 | 9 | 2500 | 5000 |

| 50 | 11 | 2500 | 5000 |

Warnings

1. Use only undamaged straps with legible capacity labels.

2. Do not exceed the rated load capacity.

3. Never knot the webbing during use.

4. Keep the webbing away from sharp edges to prevent abrasion or cutting.

5. Avoid twisting or twisting the strap during configuration.

6. Do not place objects on the strap to prevent injury.

7. Do not use the strap for load lifting or adjustment purposes.

Manufacturing Process

- Webbing (Base Material Weaving):Adopt high-strength polyester yarns as the primary raw material, leveraging the material’s inherent advantages of high tensile strength, wear resistance, and long service life to meet the core performance requirements of binding straps. Utilize professional precision weaving machinery to interlace polyester yarns in an orderly pattern, forming continuous webbing with uniform density, flat surface, and stable structure. Strictly regulate key weaving parameters (including yarn count, weaving density, and webbing width) in accordance with product specifications to ensure the base webbing achieves the designed load-bearing capacity and structural stability.

2. Dyeing (Coloration & Fixation):Post-weaving, the polyester webbing undergoes pre-treatment (degreasing and cleaning) to remove surface impurities such as oil stains and dust, enhancing the material’s dye absorption capacity for consistent coloring. Employ industry-compliant, eco-friendly, and fade-resistant dyes with high-temperature dyeing technology. Fully immerse the webbing in the dye bath, precisely controlling temperature and soaking duration to ensure uniform dye penetration. Subsequent processes include fixation, rinsing, and low-temperature drying to lock in color, preventing fading, discoloration, or color bleeding during use, cleaning, or light exposure.

3. Sewing (Manual Machine Stitching & Component Assembly):First, cut the dyed and dried polyester webbing into specified lengths using automatic cutting equipment, ensuring neat, burr-free cuts to avoid fraying. Skilled operators then use professional industrial sewing machines to assemble functional components (e.g., buckles, hooks, loops) with the cut webbing. Using high-strength polyester sewing threads (matching the base material for compatibility and durability), workers manually align the webbing and components, applying reinforced lockstitching techniques. They adjust stitching tightness based on webbing thickness and stress distribution, focusing on dense, multi-layer stitching at key stress points (e.g., buckle connections, strap joints) to eliminate loose stitches, misalignment, or thread breakage, ensuring reliable connection strength and structural integrity.

4. Packing (Inspection & Final Packaging):Conduct comprehensive quality inspections on finished binding straps, covering polyester webbing strength, dye uniformity, stitching firmness, component integrity, and dimensional accuracy. Qualified products are sorted by specification (length, width, load-bearing capacity). Each unit is individually wrapped in dust-proof material (or grouped into standard batches) and labeled with key information (specifications, load-bearing capacity, raw material, manufacturing date). Finally, products are packed into robust cartons with shock-absorbing fillers to protect against extrusion, friction, and moisture during storage and transportation.

Instructions

(1) All metal components of the strap have undergone heat treatment and professional testing. The straightforward operation ensures secure usage.

(2) Manufactured from high-strength polyester yarn, the strap exhibits low water absorption and strong adaptability to natural environments, making it suitable for securing various items during transport with professional tools.

(3) Each strap is marked with black stripes indicating breaking strength. The company can customize the presence and quantity of black stripes according to client requirements.

(4) These straps are widely employed in logistics, military transport, and railway operations for securing cargo. They are suitable for fastening and bundling diverse objects to prevent loosening.

Conclusion

In the rigorous processes of industrial production, strapping is an indispensable “safety guard.” Whether it’s steel strapping, nylon rope, or plastic film, they all utilize precise strapping techniques to protect cargo from bumps during transportation. Workers must strictly adhere to operating procedures, and every step, from material selection to tensile testing, is critical to quality and safety. This meticulous attention to detail not only demonstrates professional skill but also a commitment to responsibility. Just as strapping protects cargo, every strapping operation in industrial production is a solemn commitment to quality and safety.

HTSLINGS manufactures a full line of lifting slings and lashing equipment, from low MOQ to large series, from regular to tailor-made products, and from accessories to complete products, we aim as not only a manufacturer but a real designer of solutions in the fields to supply whatever is needed for your lifting or specific application.https://htsling.com/