In the field of material handling and lifting operations, choosing the right lifting equipment is crucial for ensuring safety, efficiency, and cost-effectiveness. Among various lifting tools, the webbing sling stands out as a versatile and reliable option, widely used in industries such as construction, manufacturing, logistics, and warehousing. This article will delve into the key types of webbing slings, including sling flat, flat slings, endless slings, and the highly popular polyester webbing sling, helping you understand their features, advantages, and application scenarios to make informed purchasing decisions.

htsling.com/product-category/flat-webbing-slings/

What is a Webbing Sling? Basic Overview

A webbing sling is a type of lifting sling made from high-strength synthetic fibers or natural fibers, designed to lift, hoist, and position heavy loads. Compared with traditional steel slings, webbing slings are lighter in weight, easier to handle, and less likely to scratch or damage the surface of the load—making them ideal for lifting delicate or finished products. The core performance of a webbing sling depends on its material, structure, and manufacturing process, among which the polyester webbing sling is favored by most industries due to its excellent comprehensive properties.

Key Types of Webbing Slings: Sling Flat, Flat Slings, Endless Slings

1. Sling Flat & Flat Slings: The Most Common Lifting Solution

Sling flat, also commonly referred to as flat slings, are the most widely used type of webbing slings in daily lifting operations. As the name suggests, they feature a flat, ribbon-like structure, which allows for large contact area with the load. This design not only distributes the load weight evenly, reducing the pressure on a single point of the load, but also minimizes the risk of the load slipping during lifting.

Flat slings are available in a variety of widths, lengths, and load-bearing capacities to meet different lifting requirements. Whether you need to lift small machinery parts in a workshop or large wooden panels in a construction site, flat slings can adapt to different working environments. In addition, compared with other types of slings, sling flat products are more cost-effective, easy to store and maintain, and have a long service life when used correctly—making them the first choice for many small and medium-sized enterprises.

2. Endless Slings: Flexible and Efficient Lifting Option

Endless slings, also known as round slings or endless webbing slings, are a type of webbing sling with a circular structure. Unlike flat slings, which have fixed lifting points, endless slings can be used in a variety of lifting configurations, such as choker hitch, basket hitch, and vertical hitch, providing greater flexibility in lifting operations.

The circular structure of endless slings enables them to wrap tightly around the load, ensuring a firm grip and reducing the risk of load displacement. They are particularly suitable for lifting irregularly shaped loads, such as pipes, cylinders, and bundles of materials. In addition, endless slings are lightweight and easy to carry, which can save labor costs and improve work efficiency. When paired with high-quality polyester material, endless slings also inherit the advantages of corrosion resistance, UV resistance, and low stretch, making them suitable for both indoor and outdoor lifting operations.

Polyester Webbing Sling: The Preferred Choice for High-Demand Scenarios

Among all types of webbing slings, the polyester webbing sling is undoubtedly the most popular one. Made from high-strength polyester fibers, this type of sling has a series of outstanding advantages that make it stand out in various lifting scenarios.

First of all, polyester webbing slings have excellent tensile strength, which can bear heavy loads without easy breakage. Secondly, they have good resistance to chemicals, moisture, and UV rays, which means they can be used in harsh environments such as humid warehouses, chemical factories, and outdoor construction sites without being easily damaged. In addition, polyester webbing slings have low stretch performance, which can ensure stable lifting of the load and avoid accidents caused by excessive stretching.

Whether it is combined with the flat structure to form flat slings or processed into endless slings, the polyester webbing sling can exert its excellent performance. For example, polyester flat slings are widely used in the automotive industry to lift car bodies and components, while polyester endless slings are commonly used in the logistics industry to hoist large packages and containers. It is worth noting that when using polyester webbing slings, it is necessary to avoid contact with high-temperature objects, as polyester fibers are not resistant to high temperatures—this is a key point to ensure the service life and safety of the slings.

How to Choose the Right Webbing Sling? Key Considerations

When selecting a webbing sling, you need to consider the following factors to ensure that it meets your actual lifting needs:

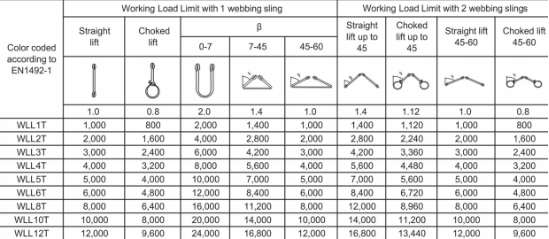

•Load Capacity: Determine the maximum weight of the load you need to lift, and choose a webbing sling with a load-bearing capacity that is greater than the load weight to ensure safety.

•Load Type: For regular, flat loads, flat slings or sling flat products are more suitable; for irregularly shaped loads, endless slings are a better choice.

•Working Environment: If the working environment is humid, corrosive, or exposed to sunlight, it is recommended to choose a polyester webbing sling due to its excellent resistance to these factors.

•Lifting Configuration: Consider the lifting method you will use (choker hitch, basket hitch, etc.), and choose a webbing sling that is compatible with that configuration. For example, endless slings are more flexible in terms of lifting configurations.

Safety Tips for Using Webbing Slings

To ensure the safety of lifting operations, it is essential to follow the correct usage methods and safety precautions when using webbing slings:

1.Before use, check the webbing sling for signs of damage, such as cuts, frays, tears, or discoloration. If any damage is found, stop using it immediately.

2.Do not overload the webbing sling. Always check the load-bearing capacity of the sling and ensure that the load does not exceed this limit.

3.Avoid contact between the webbing sling and sharp edges or corners of the load. Use edge protectors if necessary to prevent the sling from being cut.

4.When lifting the load, keep the sling straight and avoid twisting or kinking, which may reduce the load-bearing capacity of the sling.

5.Store the webbing sling in a dry, ventilated place away from direct sunlight, high temperatures, and chemicals to extend its service life.

Conclusion

The webbing sling is an indispensable lifting tool in modern industrial production, and sling flat, flat slings, endless slings, and polyester webbing sling are among the most commonly used types. Each type has its own unique features and application scenarios, and choosing the right webbing sling can not only improve work efficiency but also ensure the safety of lifting operations.

Whether you are looking for a cost-effective lifting solution for daily operations or a high-performance sling for harsh environments, the polyester webbing sling is definitely a reliable choice. When selecting and using webbing slings, always prioritize safety, follow the relevant regulations and operating procedures, and regularly inspect and maintain the slings to ensure their long-term and stable use. If you have any questions about choosing the right webbing sling, feel free to consult professional lifting equipment suppliers for personalized advice.