In the global logistics and shipping industry, the safe transportation of goods is the cornerstone of reliable supply chain operations. Whether moving bulk commodities, manufactured products, or specialized equipment, preventing cargo shifting, damage, or loss during transit is non-negotiable. This is where cargo lashing plays a pivotal role—a set of professional techniques and tools designed to secure cargo firmly in place. Among the most critical applications of cargo lashing is container lashing, which ensures the stability of shipping containers on vessels, trucks, or trains. This guide delves into the essentials of cargo lashing, the importance of container lashing, key techniques, tools, and safety standards to help you navigate the complexities of secure cargo transportation.

What is Cargo Lashing? Understanding Its Core Role in Logistics

Cargo lashing refers to the process of securing cargo using specialized equipment and methods to prevent movement, shifting, or displacement during transportation. Unlike simple tie-downs, cargo lashing is tailored to the unique characteristics of the cargo (weight, size, shape) and the mode of transport (sea, road, rail). The primary goal of cargo lashing is to distribute the forces exerted on the cargo during transit—such as vibration, acceleration, deceleration, and rough weather—across the lashing system, ensuring the safety of the cargo, the transport vehicle/vessel, and all personnel involved.

In international shipping, where goods travel thousands of miles across oceans, cargo lashing becomes even more critical. Unsecured cargo can lead to catastrophic consequences, including container tipping, cargo damage, vessel instability, and even accidents that disrupt the entire supply chain. For this reason, professional cargo lashing is not just a best practice but a mandatory requirement enforced by global regulatory bodies.

Container Lashing: The Backbone of Safe Maritime Shipping

Among all cargo lashing applications, container lashing is the most specialized and high-stakes. Shipping containers—standardized metal boxes used to transport goods globally—are stacked high on container ships, exposed to harsh marine conditions like strong winds, high waves, and constant motion. Container lashing involves securing these containers to the ship’s deck or to each other using a range of lashing equipment, ensuring they remain stable even in the most challenging sea conditions.

The importance of container lashing cannot be overstated. A single loose container can cause a domino effect, leading to the collapse of entire container stacks. This not only results in massive cargo loss but also endangers the ship’s crew and the vessel itself. Additionally, non-compliant container lashing can lead to legal penalties, delays in port clearance, and reputational damage for logistics companies. For road and rail transport of containers, container lashing also plays a key role in preventing shifting during turns, braking, or uneven terrain.

Key Cargo Lashing Equipment for Effective Container Lashing

The success of cargo lashing, especially container lashing, relies on using the right equipment tailored to the cargo and transport mode. Below are the most common and essential lashing tools:

1. Lashing Rods & Turnbuckles

Lashing rods are heavy-duty steel rods used to secure containers vertically and horizontally. They are paired with turnbuckles—adjustable devices that allow tensioning of the rods—to ensure a tight, secure fit. This combination is a staple in container lashing on ships, as it can withstand the high forces exerted by marine conditions.

2. Twist Locks & Stacking Cones

Twist locks are mechanical devices that connect adjacent containers or secure containers to the ship’s deck. They lock into the corner castings of containers, creating a rigid connection that prevents horizontal and vertical movement. Stacking cones are used to stabilize container stacks by fitting into the corner castings of the container above, ensuring alignment and reducing the risk of shifting.

3. Web Lashings & Ratchet Straps

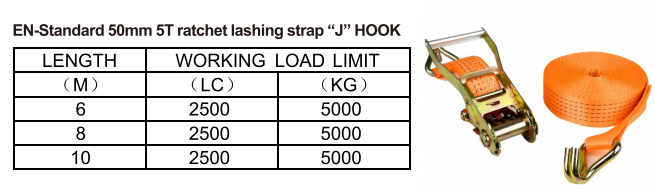

For lighter cargo or supplementary lashing, web lashings (made from high-strength polyester) and ratchet straps are used. These are flexible, easy to handle, and ideal for securing irregularly shaped cargo within containers or for additional stability in container lashing on trucks and trains.

4. Anti-Skid Mats & Dunnage Bags

Anti-skid mats are placed between the cargo and the container floor to increase friction, preventing sliding. Dunnage bags—inflatable bags placed in the gaps between cargo items or between cargo and container walls—fill empty spaces, absorbing shocks and preventing movement during transit. These are essential complementary tools in both cargo lashing and container lashing.

Best Practices for Cargo Lashing and Container Lashing

To ensure effective and compliant cargo lashing, follow these best practices, especially for container lashing:

Assess Cargo Characteristics First: Before lashing, evaluate the cargo’s weight, size, shape, and fragility. For container lashing, confirm the container’s weight (payload + tare weight) and ensure it complies with the transport vehicle/vessel’s load limits.

Use Certified Lashing Equipment: Always use lashing tools that meet international standards (such as ISO, IMO, or CSC). For container lashing, equipment like twist locks and lashing rods must be inspected and certified for strength and durability.

Distribute Tension Evenly: When lashing cargo or containers, distribute tension across all lashing points to avoid concentrated stress. For container lashing, ensure vertical and horizontal lashings are tensioned uniformly to maintain stack stability.

Fill Gaps to Prevent Movement: Use dunnage bags, foam blocks, or other filling materials to eliminate gaps between cargo items or between cargo and container walls. Empty spaces are the main cause of cargo shifting during transit.

Inspect Lashing Before and During Transit: Conduct a thorough inspection of the cargo lashing system before departure. For long-haul shipments, especially maritime transport, inspect container lashing periodically during the voyage (if possible) to re-tension or repair any loose lashings.

Comply with Regulatory Standards: Adhere to the regulations set by international bodies (IMO’s International Maritime Solid Bulk Cargoes Code, ISO 1496-1 for containers) and local authorities. Non-compliance can lead to fines, delays, or cargo seizure.

Regulatory Framework for Cargo Lashing and Container Lashing

Global logistics is governed by strict regulations to ensure the safety of cargo transportation. For cargo lashing and container lashing, key regulations include:

International Maritime Organization (IMO) Guidelines: The IMO provides detailed guidelines on container lashing for maritime transport, including load distribution, lashing equipment requirements, and safety procedures.

Container Safety Convention (CSC): The CSC sets standards for the design, construction, and testing of shipping containers, including requirements for lashing points and corner castings used in container lashing.

ISO Standards: ISO 1496-1 specifies the dimensions and ratings of shipping containers, while ISO 16852 sets standards for lashing equipment used in cargo transportation.

Compliance with these regulations is not just a legal obligation but also a guarantee of safe and reliable cargo transit.

Conclusion: Invest in Professional Cargo Lashing for Secure Transit

Cargo lashing is an indispensable part of global logistics, and container lashing is its most critical application, ensuring the safe transport of goods across oceans, roads, and rails. By understanding the core principles of cargo lashing, using certified equipment, following best practices, and complying with regulatory standards, logistics companies, shippers, and transporters can minimize the risk of cargo damage, accidents, and supply chain disruptions.

Whether you’re shipping containers internationally or transporting bulk cargo locally, investing in professional cargo lashing services and high-quality lashing equipment is a smart decision. It not only protects your valuable cargo but also enhances your reputation as a reliable partner in the supply chain. For complex cargo or container lashing needs, consult with experienced lashing professionals to ensure compliance and maximum safety.