Introduction

Ratchet tie down straps, also called ratchet straps, are important tools used to hold cargo in place during transport. These straps are commonly used on trucks, trailers, ships, and in warehouses to keep things from moving or falling. Unlike lifting slings, which are rated by Working Load Limit (WLL), ratchet straps are rated by Breaking Strength (BS)—the maximum weight they can handle before breaking. This guide will explain where ratchet straps are used, the different standards in different countries, and the details of their parts.https://htsling.com/product-category/ratchet-tie-down-straps/

Differences in Standards: Europe, America, and Australia

Different countries have different rules for ratchet straps. The main ones are the European Standard (EN), the American Standard (WSTDA), and the Australian Standard (AS/NZS).

- European Standard (EN 12195-2)

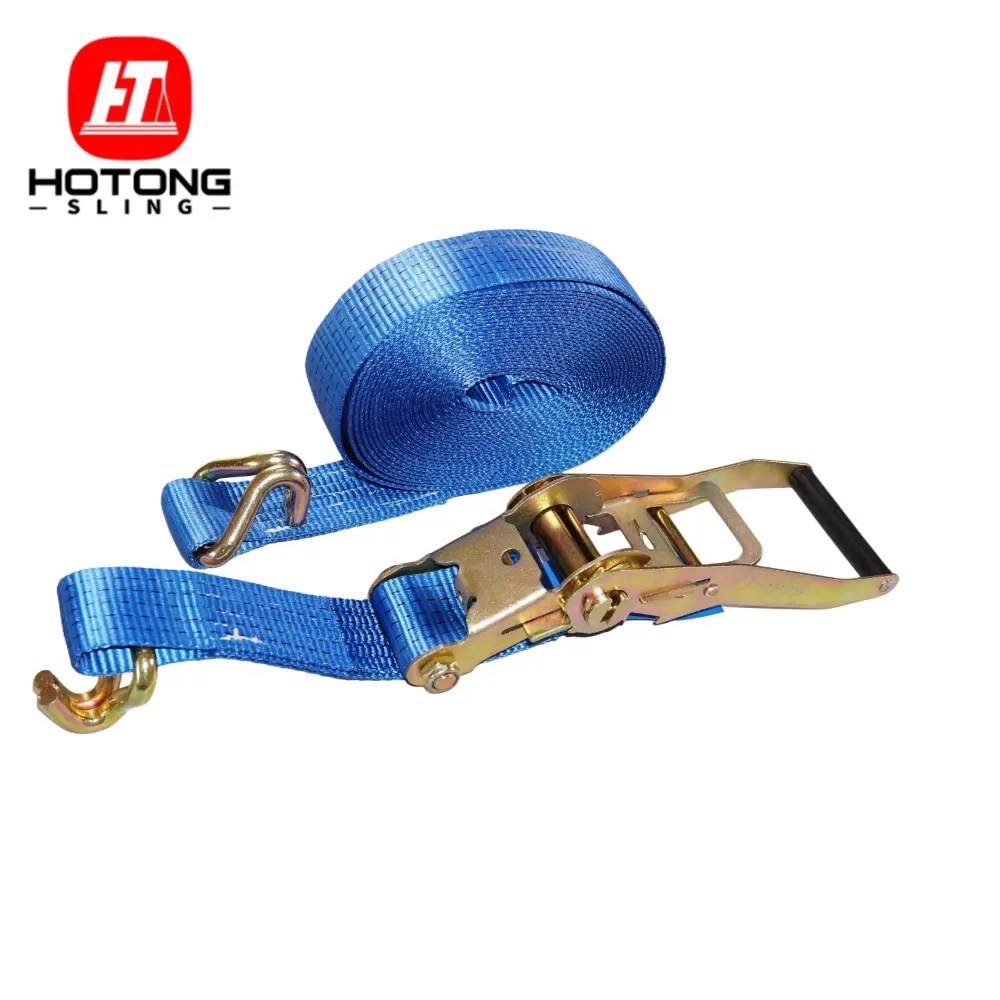

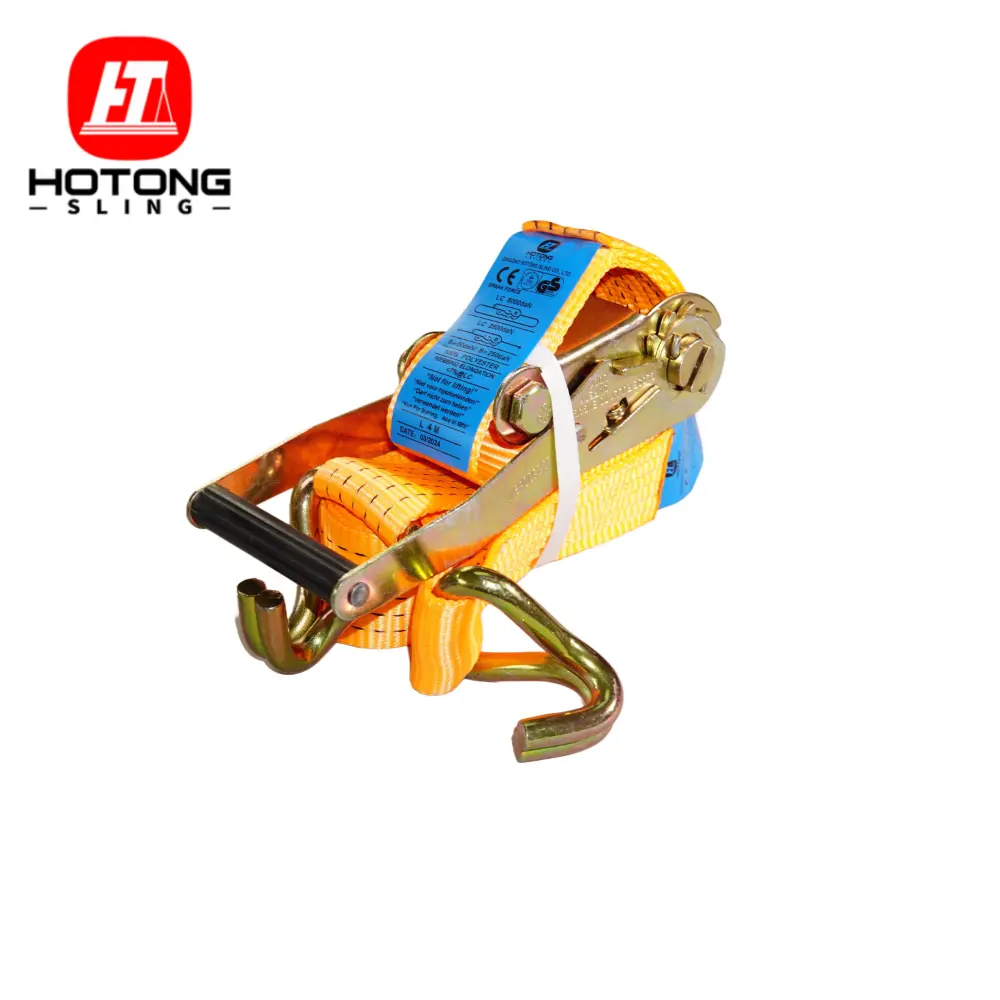

The European rule focuses on Lashing Capacity (LC), meaning the force a strap can handle safely during use. It’s measured in daN (1 daN ≈ 1 kg). This standard requires clear labeling on the strap, showing its lashing capacity and breaking strength.

| EUROPEAN STANDARD | ||||||||||||

| SAFETY FACTOR | 2:1 | |||||||||||

| WIDTH | 25MM | 35MM | 50MM | 75MM | 100MM | |||||||

| LOAD CAPACITY(daN) | 400 | 500 | 750 | 1000 | 1500 | 1000 | 1500 | 2000 | 2500 | 4000 | 5000 | 5000 |

| BREAKING LOAD(daN) | 800 | 1000 | 1500 | 2000 | 3000 | 2000 | 3000 | 4000 | 5000 | 8000 | 10000 | 10000 |

| LENGTH | 6M, 8M, 10M, 12M | |||||||||||

| HOOK | S hook, Double J hook, E-fitting, U hook | |||||||||||

| SURFACE | Usually use orange, blue, yellow, green color. Each black line represents 1 ton of rated load capacity, making it easier for workers to quickly identify. | |||||||||||

| USE | Common in Europe for transport and logistics | |||||||||||

2. American Standard (WSTDA-T-1)

The American rule measures Breaking Strength (BS), which is the maximum force a strap can handle before breaking. It’s measured in pounds (lbs). American straps are often heavier and come in longer lengths than European ones.

| American STANDARD | |||||||

| SAFETY FACTOR | 3:1 | ||||||

| WIDTH | 1″ | 2″ | 3″ | 4″ | |||

| WLL(LBS) | 800 | 1000 | 1500 | 3333 | 5400 | 5400 | 6200 |

| MBL(LBS) | 2400 | 3000 | 4500 | 10000 | 16200 | 16200 | 18600 |

| LENGTH | 10, 15, 20, 27, and 30 feet | ||||||

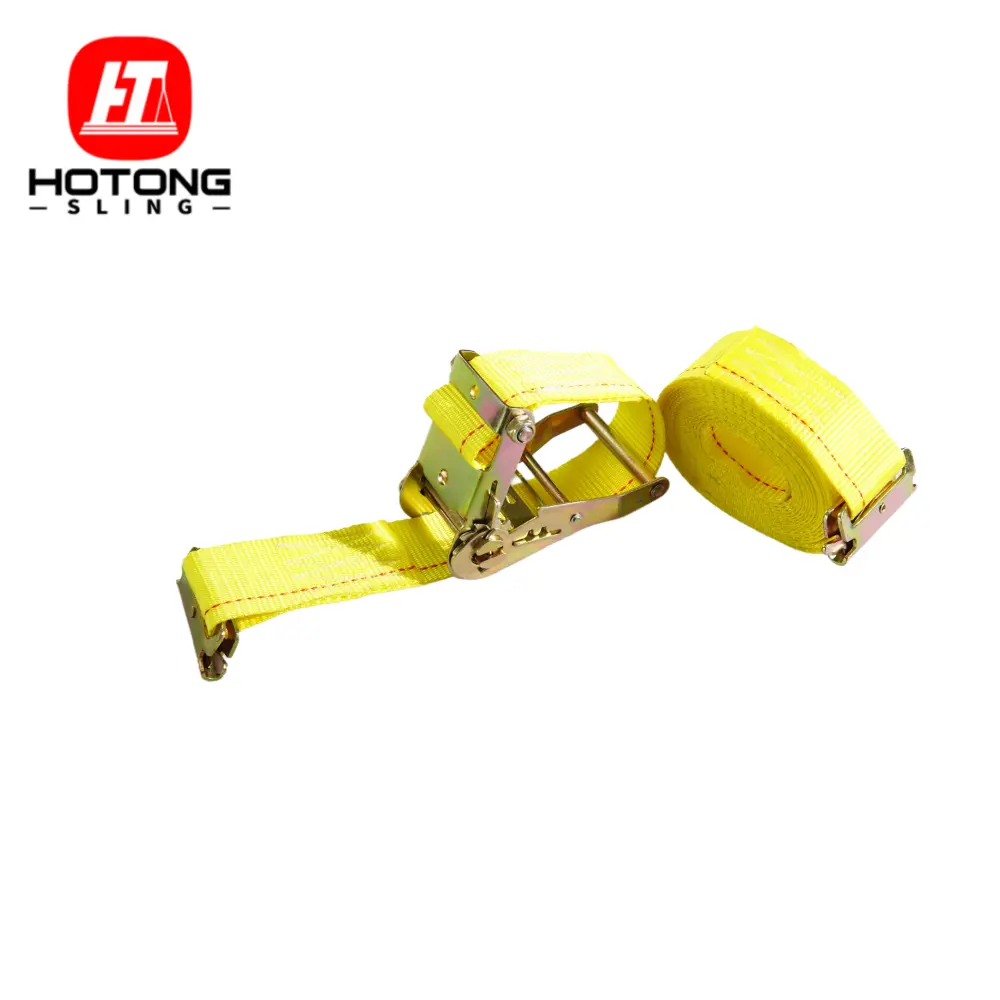

| HOOK | Flat hook, S hook, Double J hook, E-fitting, Chain hook | ||||||

| SURFACE | Usually yellow, with a black or red line in the middle. | ||||||

| USE | Common in North America for transport and logistics | ||||||

3. Australian Standard (AS/NZS 4380)

The Australian rule is like the American one but also focuses on UV resistance to handle outdoor conditions. Since Australia has a harsh sun, UV protection is essential to prevent straps from weakening over time.

| AUSTRALIAN STANDARD | ||||

| SAFETY FACTOR | 2:1 | |||

| WIDTH | 25MM | 35MM | 50MM | 75MM |

| LOAD CAPACITY(daN) | 750 | 1500 | 2500 | 5000 |

| BREAKING LOAD(daN) | 1500 | 3000 | 5000 | 10000 |

| LENGTH | 5M, 6M, 9M | |||

| HOOK | Mostly Swan hook | |||

| SURFACE | Usually blue. Each black line represents 1 ton of rated load capacity, making it easier for workers to quickly identify. | |||

| USE | Used in Australia for securing cargo outdoors | |||

Parts of a Ratchet Tie Down Strap

A ratchet strap has three main parts: the ratchet mechanism, the strap, and the hooks. Each part affects how strong and useful the strap is.

- Ratchet Lashing Tensioner

This part tightens the strap and locks it in place. It includes a handle and a locking system. The ratchet mechanism is what makes these straps more secure than simple ropes or bungee cords.

Handle Types

- Aluminum handle: Lightweight and rust-resistant, good for boats and marine use.

- Plastic handle: Comfortable to hold, ideal for frequent use without causing hand strain.

- Steel handle: Strong and durable, for heavy-duty work in construction and industry.

Surface Finishes

- Yellow Zinc: Rust-resistant, with a yellow finish that’s easy to spot.

- White Zinc: A silver finish that resists rust and looks clean.

- Black Electrophoresis: A sleek black finish that offers strong rust protection.

Handle Sizes

- Extended: Gives more leverage for heavy loads, making it easier to tighten the strap.

- Long: For medium to large cargo, providing a good balance between leverage and comfort.

- Short: Good for general use and lighter loads.

2. Strap

The strap’s width and breaking strength are important for choosing the right strap. The material is usually made of polyester, which is strong and resistant to weather and stretching.

| Strap Width | Breaking Strength (BS) |

| 25mm / 1 inch | 1 ton |

| 35mm / 1.5 inches | 2 tons, 3 tons |

| 50mm / 2 inches | 2 tons, 3 tons, 4 tons, 5 tons |

| 75mm / 3 inches | 8 tons, 10 tons |

| 100mm / 4 inches | 10 tons |

- Standard Lengths: 6m, 8m, 10m, 12m

- American Lengths: 10ft, 15ft, 20ft, 27ft, 30ft

- Custom Lengths: Can be made on request

- Example: A 50mm strap with a breaking strength of 5 tons can be used to secure large pieces of industrial equipment during transport.

3. Hooks

Hooks attach the strap to the cargo or vehicle. Different hooks are used for different jobs and markets.

Double J Hook: For heavy cargo; common in Europe and North America. It’s shaped like the letter J and hooks securely onto truck beds and trailers.

S Hook: For light jobs like moving furniture; popular in North America and Europe. It’s easy to use and works well with car roof racks.

Flat Hook: For securing flatbed loads; often used in the trucking industry. It provides a wide surface area for better grip. Very popular in North America.

Swan Hook: Designed for securing heavy loads; commonly used in Australia. This hook is ideal for industrial applications such as construction, shipyards, and factories, where versatility and strength are crucial.

Claw Hook: For tough jobs requiring extra strength; popular in Australia and North America. It’s often used to secure heavy machinery.

E Track Hook: For inside shipping containers; used in shipping to keep cargo from moving inside the container.

Example: An E Track Hook is often used by shipping companies to secure furniture inside containers to prevent damage during ocean transport.

Where Ratchet Tie Down Straps Are Used

Ratchet straps are useful in many industries. Their main job is to keep cargo steady and safe during transport, preventing accidents and damage.

- Transportation and Shipping

In the transport industry, ratchet straps secure goods on trucks, trailers, and containers. They stop cargo from moving or falling, which could cause accidents. For example, when transporting pallets of goods or large machines, ratchet straps keep them from sliding around or tipping over during sharp turns or sudden stops.

- Common Uses: Holding pallets, machines, and heavy equipment

- Popular in: North America, Europe, Australia, South America, Middle East, Asia

- Example: Truck drivers often use 50mm ratchet straps to secure heavy machinery to flatbed trailers, preventing any movement during long-distance transportation.

2. Construction

On construction sites, ratchet straps hold heavy equipment and building materials in place. For instance, scaffolding parts and steel beams need to be tightly secured when transported to prevent them from falling and causing injuries.

- Common Uses: Securing excavators, bulldozers, and materials

- Popular in: North America, Europe, Australia, South America, Middle East, Asia

- Example: Construction companies may use 35mm straps to secure smaller tools and equipment, while larger 50mm straps are used for heavy vehicles and machinery.

3. Home and Outdoor Activities

For home moves or outdoor activities like camping, ratchet straps can secure furniture, bikes, and other gear. For example, during a move, a ratchet strap can keep a refrigerator in place in the back of a moving truck, preventing it from tipping over.

- Common Uses: Moving furniture, securing bikes and kayaks

- Popular in: North America, Europe, Australia, South America, Middle East, Asia

- Example: Campers often use S hooks with ratchet straps to secure kayaks to roof racks, ensuring they don’t move during travel.

FAQ

To help us understand what you need and give you the right price, please tell us these details:

- Breaking Strength: How much weight or force does the product need to hold?

- Handle Material and Color: Do you want a handle made of aluminum, plastic, or steel? What color do you prefer—yellow, silver, or black?

- Strap Width and Length: What size and length of the strap do you need?

- Hook Type: Which hook do you need? Double J, S Hook, Flat Hook, Claw Hook, or E Track Hook?

By giving us this information, we can help you faster and find the right product for your needs. We look forward to your message!

We are a factory that makes ratchet tie-down straps, and we’re your best choice! As a direct factory, we can give you both great prices and high-quality products. With our experience and careful work, every strap is made to be strong and reliable.

When you choose us, you’re working with a factory you can trust. We know what you need and make sure you get the best. Let us help you secure your loads safely and easily. We are ready to be your best partner!https://htsling.com/