In industrial lifting and hoisting operations, the endless round sling, with its flexible adaptability, safety, and durability, is gradually replacing traditional metal slings and becoming a core lifting tool in manufacturing, logistics, construction, and other fields. Whether transporting precision equipment or lifting heavy components, the endless round sling’s lightweight design and stable performance address the complex operation and damage-prone nature of traditional slings. This article will comprehensively analyze the endless round sling from the perspectives of product advantages, applicable scenarios, selection methods, and maintenance tips, using key keywords such as lifting round sling and polyester sling, to help companies improve lifting efficiency and reduce safety risks.

Part1. Understanding the Endless Round Sling: Why has it become a new favorite in the lifting industry?

The endless round sling, also known as a circular woven sling, is typically made of high-strength polyester sling and is formed into a closed loop structure through a special weaving process. It offers advantages unmatched by traditional slings, which can be summarized in the following four points:

High Safety Factor and Excellent Cushioning Performance

Compared to metal chains and wire ropes, the polyester sling used in the endless round sling boasts a moderate elongation at break. This allows it to slowly stretch in the event of an accidental overload, effectively cushioning impact loads and preventing accidents caused by sudden breakage. Furthermore, the ring structure has no sharp edges, eliminating sparks from metal friction. It is suitable for flammable and explosive environments such as chemical, oil, and gas industries, and is far safer than conventional lifting round slings.

Lightweight Design for Easier Operation

The endless round sling weighs only 1/6-1/10 of a metal sling of the same load capacity, making it easily transportable and attachable by a single person, significantly reducing labor costs. For example, a 5-ton rated endless round sling weighs only approximately 3 kg, while a wire rope sling of the same load capacity can weigh over 20 kg. The convenience of the endless round sling is particularly evident when working at height or in confined spaces. 3. Work piece Protection, Compatible with Various Materials

The polyester sling has a soft and smooth surface, providing a large contact area with the work piece. It evenly distributes pressure and prevents damage to easily scratched materials such as metal, glass, and stone. For lifting precision equipment and handicrafts, the endless round sling can replace traditional lifting round slings, reducing work piece repair costs and improving product quality.

Weather-Resistant and Durable, Extended Lifespan

The high-quality endless round sling uses polyester sling with excellent acid, alkali, UV, and aging resistance. It operates stably in temperatures ranging from -40°C to 100°C. It can withstand harsh environments such as humid, outdoor, and chemical environments, with a service life up to 2-3 times that of traditional steel wire rope, reducing the frequency and cost of lifting equipment replacement.

Part2. Endless Round Sling Application Scenarios: These Industries Are Relying on It to Improve Efficiency

As a highly versatile lifting tool, the endless round sling, with its flexible adaptability, has been widely used across multiple industrial sectors, becoming a valuable aid for companies to reduce costs and increase efficiency:

1. Manufacturing: A “Protector” for Precision Equipment Transportation

In the automotive, electronics, and machinery manufacturing industries, the endless round sling is used for on-site transportation and assembly of precision work pieces such as engines, machine tools, and display screens. The soft polyester sling conforms to curved work piece surfaces, preventing scratches. Its ring-shaped structure allows for quick attachment and can be used with cranes and forklifts, significantly reducing lifting time and improving production line efficiency.

2. Logistics and Warehousing: An Efficient Assistant for Cargo Loading and Unloading

In logistics applications such as e-commerce, cold chain logistics, and ports, the endless round sling is an ideal choice for loading and unloading containers, parallelized cargo, and cold chain equipment. Compared to conventional lifting round slings, its loop-shaped design eliminates the need for additional hooks and allows for direct hooking of cargo, making it suitable for frequent loading and unloading. It can reduce the lifting time per shipment by over 30%, helping logistics companies improve turnover efficiency.

3. Construction Engineering: The Weather-Resistant Expert for Outdoor Lifting

When lifting building components such as steel structures, prefabricated panels, and glass curtain walls, the endless round sling withstands outdoor wind, rain, and UV rays, and its performance is unaffected by metal corrosion. Furthermore, its polyester material eliminates the risk of electrical conductivity, making it far safer than metal slings when operating near high voltages and complying with construction industry safety regulations.

4. Chemical Industry: The Expert in Corrosive Environments

When lifting chemical storage tanks, plastic pellets, and acid and alkali solution containers, the endless round sling’s polyester sling offers strong corrosion resistance, eliminating the risk of breakage associated with traditional metal slings. Its closed loop structure also prevents material leaks, ensuring worker safety, making it the preferred lifting round sling for chemical companies.

III. Endless Round Sling Selection Guide: 3 Steps to Choose the Right Product Selecting the right endless round sling is crucial for ensuring lifting safety and improving efficiency.

Based on the lifting round sling selection criteria, you can accurately match your needs in the following 2 steps:

1.Select an endless round sling that meets safety standards based on the weight of the load being lifted.

The industry-standard safety factor is ≥6:1, meaning that if lifting a 5T load, you need to choose a product with a rated load ≥5T; if dynamic loads are involved, or the lifting angle is ≤60°, you need to reserve an additional 10%-20% load margin to avoid overloading. For example, for lifting an 8T load at a 45° angle, it is recommended to choose an endless round sling with a rated load ≥10T.

2. Select the right material and specifications based on the working conditions.

Material selection: Prioritize endless round slings made of polyester sling, as they offer superior overall weather resistance and strength. For even greater abrasion resistance, choose polyester slings with an abrasion-resistant coating. In humid environments, waterproof lifting round slings can be used in conjunction.

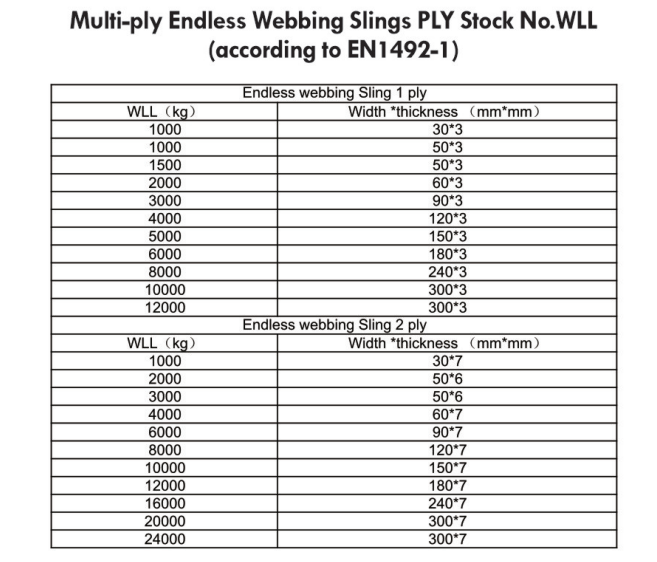

Specification determination: Select the webbing diameter based on the size of the object being lifted; a larger diameter results in a stronger load-bearing capacity. Simultaneously, confirm that the inner diameter of the ring is compatible with the hook and lifting ring to avoid the risk of detachment due to size mismatch.

Part4. Conclusion

As a highly efficient lifting tool based on a polyester sling, the endless round sling has become a mainstream choice in the industrial lifting industry due to its safety, lightness, and durability. Whether it’s precision transshipment in manufacturing or efficient loading and unloading in logistics, choosing and effectively utilizing the endless round sling can help companies reduce costs and improve efficiency. In the future, with the advancement of lifting round sling technology, intelligent and environmentally friendly endless round slings will further promote the development of the lifting industry.

If you need a customized endless round sling for your specific application, or would like to learn more about the material properties of polyester slings, please consult a professional lifting equipment manufacturer for a personalized solution to ensure safer and more efficient lifting operations.https://htsling.com/product-category/flat-endless-sling/