When you think about lifting heavy objects or materials, you probably think of cranes, hooks, or ropes. But one of the safest and most reliable tools for this job is a flat endless webbing sling. These slings are commonly used in industries where lifting heavy loads safely and efficiently is a top priority. But what exactly are they, and how do they work? Let’s take a closer look.https://htsling.com/product-category/flat-webbing-slings/

Product Overview: What is a Flat Endless Webbing Sling?

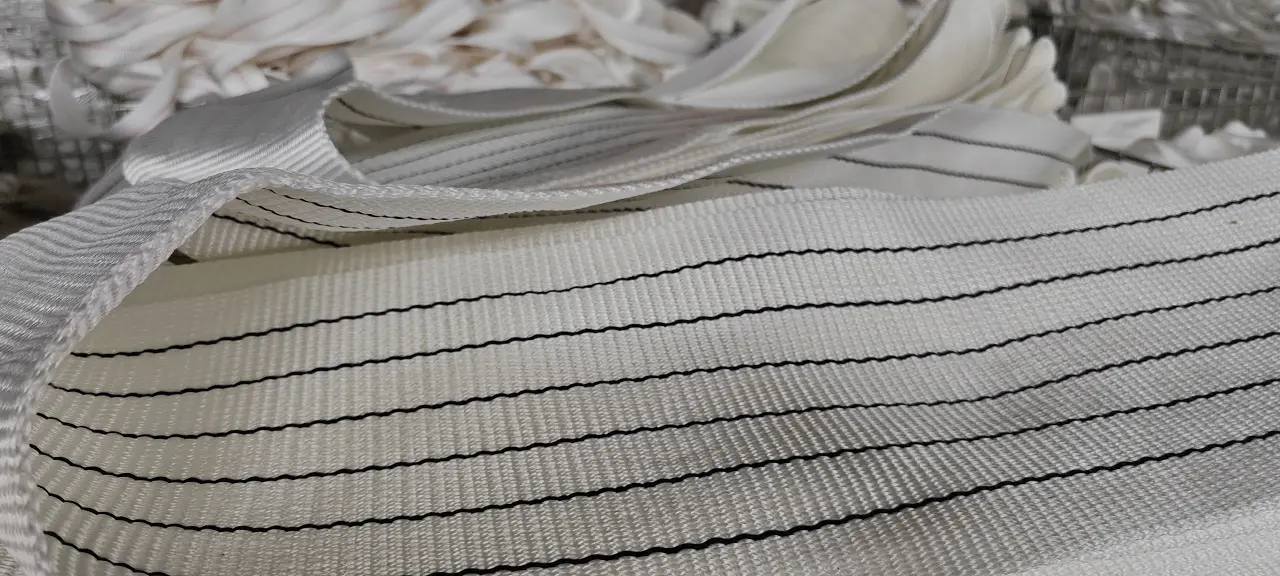

A flat endless webbing sling is a type of lifting strap made from strong, durable fabric. Unlike other lifting slings, an endless webbing sling has no end. It is one continuous loop of material. This design makes it very flexible and strong, as it evenly distributes the weight of the load being lifted.

These slings are typically made from synthetic materials like polyester. Polyester is often used because it has high strength, is resistant to most chemicals, and works well in different weather conditions.

The “flat” in flat endless webbing sling refers to its shape. The sling is flat rather than round, giving it a larger surface area, which helps prevent damage to the load and ensures a more secure lift. The absence of ends, meaning it’s one continuous piece, allows the sling to be more flexible and easily used.

How Does a Flat Endless Webbing Sling Work?

The main function of any lifting sling is to carry weight safely. The flat endless webbing sling does this by using a principle called load distribution. When you lift an object with a webbing sling, the weight of the load is spread out evenly along the length of the sling. This even distribution helps prevent any one part of the sling from being overloaded, reducing the risk of damage or failure.

When you attach the sling to a load and lift it, the fabric of the sling absorbs the weight and creates a stable grip. This makes it safer to lift irregularly shaped objects because the fabric can adjust to the shape of the load. The flat, wide design helps to protect delicate items by creating a larger contact area.

Because it is endless, the sling can be used in a variety of ways. It can be doubled over to lift heavier loads or used in a single loop depending on how much weight needs to be lifted. This versatility makes it a popular choice for many types of lifting jobs.

Specifications and Types: Choosing the Right Sling for the Job

Flat endless webbing slings come in various sizes, strengths, and materials to suit different lifting needs. The length of the sling is an important factor in how it will be used. Shorter slings are good for lifting objects that are not too heavy, while longer slings can be used for larger loads or when extra length is needed to reach the lifting point.

The width of the sling affects how much weight it can lift. Wider slings distribute weight over a larger area, which is helpful when lifting heavy or delicate items. Each sling has a specific weight capacity, which indicates the maximum weight it can safely lift. This is often marked with a label on the sling itself. It’s important to never exceed the rated capacity of the sling to prevent accidents.

Most flat endless webbing slings are made from either polyester or nylon. Polyester is strong and resistant to chemicals, while nylon is more flexible and stretches under load, which can sometimes be beneficial in lifting operations. Slings are designed with a safety factor, which is a multiple of the rated load capacity. A typical safety factor might be 5:1, meaning the sling is designed to hold five times its rated load. Always choose a sling with a safety factor that matches the load you intend to lift.

Different types of flat endless webbing slings are available, depending on their intended use. Some slings may come with special coatings to resist weathering, others may be reinforced for extra strength, and there are even color-coded options to help identify different weight capacities easily.

Common Applications: Where and When Are Flat Endless Webbing Slings Used?

Flat endless webbing slings are used in a variety of industries, from construction to logistics, because of their versatility and safety features. In construction, heavy materials like steel beams, concrete blocks, and large machinery need to be lifted into place. A flat endless webbing sling is ideal because it can handle heavy loads and is easy to attach to lifting cranes. The flat shape helps to distribute the weight evenly, protecting the materials being lifted from damage.

In shipping and logistics, goods often need to be loaded and unloaded from containers, ships, or trucks. Flat endless webbing slings are commonly used in these situations to safely lift and move packages or equipment without damaging them. They are also useful in the warehouse when moving heavy pallets.

In factories and warehouses, lifting heavy items like large containers, machinery parts, or equipment is a daily task. The flat webbing sling can be used to lift items of different shapes and sizes without damaging the product or causing accidents. When transporting vehicles or large equipment, the sling can be used to lift them onto trucks or trailers. The flat, wide design of the sling prevents damage to the vehicle’s body and ensures a safe and stable lift.

In agriculture and forestry, lifting large bundles of crops or logs is often necessary. A flat endless webbing sling is perfect for this, as it can lift irregularly shaped items like logs without causing damage.

Conclusion

Flat endless webbing slings are a key tool in lifting and moving heavy objects safely and effectively. Their ability to distribute weight evenly, along with their flexibility and strength, makes them ideal for a wide range of applications. By understanding how they work, choosing the right specifications, and using them in the proper scenarios, workers can ensure that lifting tasks are done safely and efficiently. Whether in construction, logistics, or industrial settings, these slings play a critical role in modern lifting operations.https://htsling.com/